Q37 Hanger Type Shot Blasting Machine

Q37 Hanger Type Shot Blasting Machine

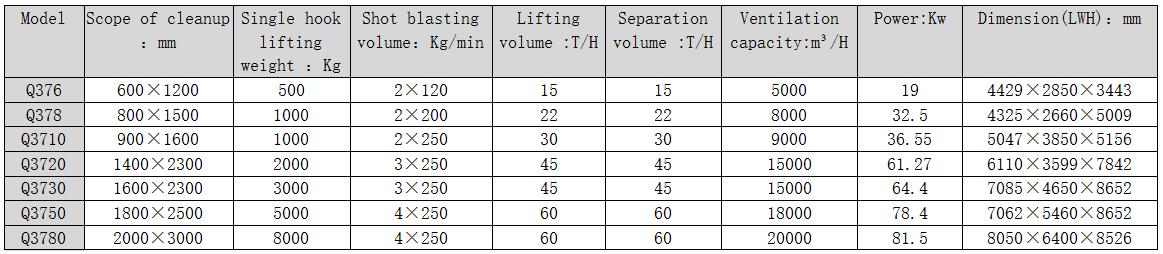

Q37 series hook type shot blasting machine is the most widely used shot blasting equipment, single hook lifting weight 500-8000Kg, shot blasting workpiece size range can reach 600*1200mm-2000*3000mm, shot blasting angle through CAD calculation of the best shot blasting line, equipped with steel shot recovery device and dust removal equipment.Product Introduction

Q37 type shot blasting machine is hook type shot blasting equipment, with the following characteristics.

Adopt the cantilever (or direct link, i.e. motor directly embedded) centrifugal blast machine with large blast volume and high blast speed to improve the cleaning efficiency and obtain satisfactory cleaning quality.

When cleaning the workpiece, the hook lifts the workpiece into the blast room blast area, close the door, start the dust removal system, separator, hoist, screw conveyor, shot blasting machine and supply shot gate, etc., can be blast cleaning work, the workpiece can move back and forth while rotating, so as to thoroughly clean up the dead corner of the workpiece,cleaning is complete, lifting out of the cleaning room, unloading, on the pieces.

Simulated blast diagram and all drawings of the blast machine are drawn using computer-aided design (CAD), the selection and arrangement of the blast machine is more reasonable. Improve the utilization rate of the projectile and labor productivity, to ensure the cleaning effect and reduce the wear and tear on the chamber shield.The cleaning room adopts wear-resistant steel plate protection, and the dust removal method adopts bag dust removal, and the electric control system has manual and automatic operation.

No pit. Not only saves the construction time and cost of the pit foundation, but also solves the problem of rusting and caking of shot sand in the elevator due to water in the pit used by customers in southern China.

the series is divided into single hook type and double hook type, double hook type with Y-type track, shot blasting workpiece and loading and unloading workpiece can be carried out separately, use the double hook form, the hook has its own travel track, do not need to change track when working.

Φ0.8-2.0 cast steel shot or steel wire cut shot, hardness HRC40-45, using air-controlled shot gate valve, independent control of shot supply, relying on the cylinder for long-distance control of shot blasting volume.